The Complete Process of Custom Hoodie Manufacturing

The Complete Guide to Custom Hoodie Production: From Design to Finished Product

In the fashion industry, custom hoodies have become a powerful way for brands to express identity and build recognition. Whether for streetwear labels, corporate groups, or independent designers, understanding the full production process is essential. This article provides a systematic breakdown of custom hoodie manufacturing—from design and material selection to sampling and mass production—helping you master professional-level customization solutions.

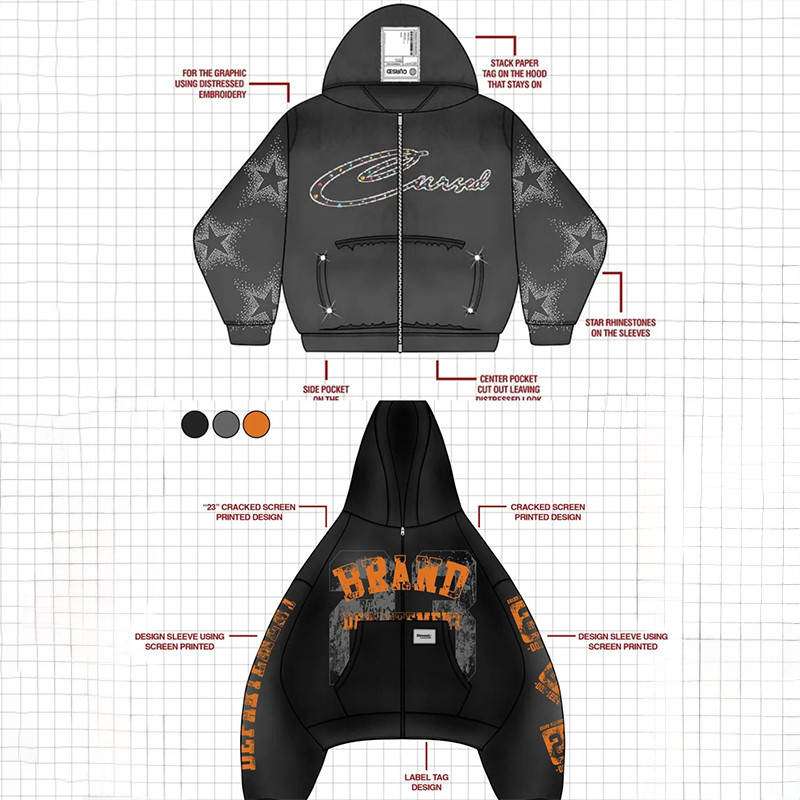

1. Design Phase: Precise Matching of Styles and Techniques

(1)Style Selection:

1)Classic hooded style: Streetwear staple, fits most body types

2)Crewneck casual style: Minimalist and versatile, ideal for layering

3)Oversize cut: Trend-forward with structured silhouette

4)Functional designs: Zippered/details or paneled variations

(2)Pattern & Technique Matching Guide:

1)Large color-block designs → Screen printing

Benefits: Vibrant colors, cost-effective for bulk orders

Note: Requires white underbase for dark fabrics

2)Intricate small logos → Embroidery

Recommended: 15+ stitch density

Best for: Brand emblems, small text

2. Fabric and Trims Selection

| Type | Key Characteristics | Ideal For |

| 100% Cotton | Breathable, prone to pilling | Everyday basics |

| Cotton-Poly Blend | Wrinkle-resistant, durable | Promotional/budget pieces |

Fleece | Brushed interior, warmth-focused | Winter collections |

| Organic Cotton | Eco-friendly, premium handfeel | Sustainable brands |

Critical Trim Components:

Drawstrings: Cotton/polyester with metal aglets (custom colorable)

Zippers: YKK® for durability (5mm tooth standard)

Pocketing: Loopback jersey lining for comfort

Labels: Woven/printed options (RFID embedding available)

3. Sampling & Revisions (3-Iteration Principle)

(1)Proto Sample

Verify pattern & dimensions against tech packs

Evaluate fabric handfeel & GSM (e.g. 300gsm for → autumn/winter styles)

(2)Fit Sample

Fitting adjustments: sleeve length/hood circumference/hem tightness

Process testing: print color fastness/embroidery thread tension

(3)Pre-Production Sample (PP Sample)

Finalize construction details (stitch density/serging methods)

Confirm trim specifications (drawstring length/zipper functionality)

Note: Each sampling cycle requires 7-10 days (include buffer time).

4. Mass Production Process (For 1000-Piece Order)

(1)Cutting

Automated cutting with ≤1mm tolerance

Layered cutting to prevent fabric distortion

(2)Printing/Embroidery

Screen printing: Requires separate screens per color

Embroidery: Minimum 15-stitch density

DTG: Requires pretreatment for dark fabrics

(3)Sewing

Key techniques:

Double-needle stitching (reinforced seams)

Triple-stitched hems (streetwear standard)

Reinforced hood brims

5. Delivery & Quality Inspection

Delivery Process:

(1)Inspection Standard

AQL 2.5 sampling inspection

Key checks: print/embroidery durability, size tolerance (±1.5cm), trim functionality

(2)Packaging Requirements

Individual PE bags + crush-proof cartons

Clear labeling: style/color/size

(3)Logistics Options

Small batches: express delivery

Bulk orders: dedicated logistics/ocean shipping

Complete Your Order and Enjoy Fast Shipping

Once your custom design is complete, submit your order, and we’ll get to work on crafting your piece with premium materials and expert distressing techniques. And don’t worry — we offer fast shipping, so you won’t have to wait long to receive your new custom streetwear.

Contact Us and Start Your Custom Journey Today!

If you're ready to design your own custom streetwear or have any questions, we’re here to help! Our customer service team is ready to ensure you get the best customization experience possible.

📞 Phone: [86-13428400973]

📧 Email: [info@chanjoye.com]

🌐 WhatsApp:[https://wa.me/8618025298509]

https://www.chanjoye.com/contact-us.htm

Click the link above to start designing your custom streetwear today. We can’t wait to help you express your bold style!